Bender provides electrical safety solutions in surface mining. The large excavators used for open-pit mining use many different drives - both medium and low voltage. While portable loads often supply power from resistance grounded sources, they can also use ungrounded power for special drive circuits. The large drives are often ungrounded on the load side of the drive. The secondary insulation can be monitored by an ISOMETER® with a coupling device where required. A residual current monitoring system (RCMS) can be used for low voltage drives that are not transformer isolated. If the low voltage drive is on an ungrounded supply, the ISOMETER® insulation monitoring with EDS, as in both cases, the faults occurring are immediately detected and reported to improve availability significantly.

Electric motors are generally employed for conveyor belts used in mining, driven by soft starters or frequency converters. However, these often generate harmonics and DC currents, which are typically not present in an AC system. With regular ground-fault protection or simple insulation monitors (e.g. 3 lamp method or 2 voltmeter process), these circuits cannot be monitored and adequately protected. These specialized applications require more modern monitoring equipment that can quickly recognize and report insulation breakdown and leakage current to the ground. Some standards even require a quick shutdown, which can be achieved via ground-fault monitoring devices.

Heavy haul trucks are increasingly being powered by electric drives or wheel motors. Bender ground-fault monitoring devices monitor the complete electrical drive system for utility vehicles including all electric or hybrid drives (often single-wheel drive). This means they provide effective protection against electric shocks and minimize the fire risk. In addition to onboard electrical protection Bender relays are also installed to protect equipment used to work on these trucks. The Lifeguard can be used on loads fed from welding receptacles in shops and wash bays.

Crushers are needed in mining to break down the ore extracted from the ground. These use huge, powerful motors powered by soft starters or frequency converters due to their size. The resulting harmonics and DC currents are not recognized by GFCIs. The use of an adjustable RCMA residual current monitoring system (ground-fault monitor) is therefore advisable to improve fault detection.

Mines require power for extraction and processing. This power can be supplied by generators or local utilities, depending on where the mine site is located. Larger mines may have utility power crews that work on high voltage, but most often, mines deal with medium voltage power. The medium voltage is either used directly by large machines or is transformed to lower voltage for smaller equipment and loads. All three standard system grounding methods (solidly, resistance, and ungrounded) may be used on a mine site. For grounded systems, the Bender residual current monitors (RCM), Neutral grounding resistor monitors (NGRM’s), and ground-check relays offer sensitive and cost-effective protection. Bender ISOMETER®s are ideal for insulation monitoring and trending for ungrounded systems, including the secondaries of large drives.

Complete neutral grounding resistor packages can be supplied by Bender, complete with components required for continuous monitoring. Typically the NGRs are mounted outdoors near the power transformer.

Continuity of Service

Control fault current and have alarm-only operation on the first ground-fault.

Ease of Retrofit

Ability to easily and cost-effectively upgrade older equipment.

Improved Safety

Reduces potential for shock and arc flash hazard. Arc flash is reduced by as much as 95%. Automatic fault location at feeders and loads can eliminate the need to open doors on energized equipment during troubleshooting.

Reduces Maintenance Costs

Accuracy of detection leads to a decrease in maintenance costs and the need for human interaction with the system.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| 2020 Guidelines (US) | Technical Information | 1.9 MB | EN | 2020/06/1515.06.2020 | |

| Overview Brochure | Product Overviews | 10.3 MB | EN | 2023/10/0202.10.2023 | |

| Mining | Market Segment Brochures | 2.6 MB | EN | 2021/08/2626.08.2021 | |

| Bender Industry Application | Market Segment Brochures | 19.1 MB | EN | 2022/08/1919.08.2022 | |

| Electrical Protection Selection Guide | Market Segment Brochures | 4.1 MB | EN | 2022/08/2626.08.2022 | |

| High-Resistance and Low-Resistance Grounding Systems | Market Segment Brochures | 4.2 MB | EN | 2022/08/2929.08.2022 | |

| EDS - Automatic Fault Location | Flyers | 1.1 MB | EN | 2021/04/2828.04.2021 |

Products

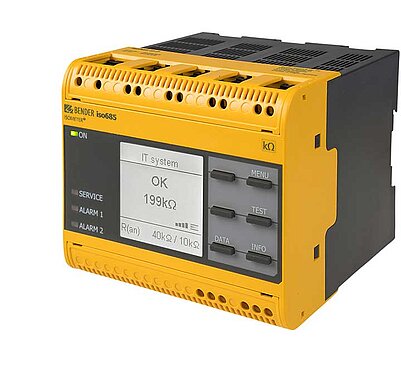

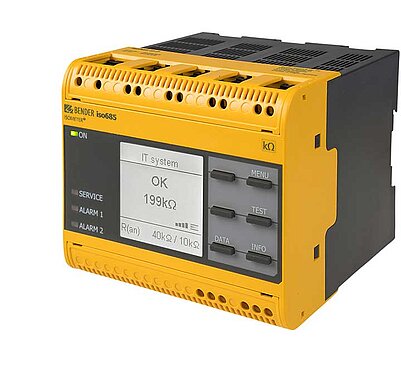

Ground-fault detector for ungrounded AC/DC systems

Four-channel DC, AC and pulse current sensitive residual current monitor for earthed AC, AC/DC and DC systems

Multi-channel AC/DC ground-fault monitor

Multi-channel AC/DC ground-fault monitor with individual relay outputs

![[Translate to North American English:] NGRM700](jpg/csm_ngrm700_01_web_list_97278228d7.jpg)

Monitor for use in high-resistance grounded systems

Ground-fault detector for ungrounded AC/DC systems

Four-channel DC, AC and pulse current sensitive residual current monitor for earthed AC, AC/DC and DC systems

Multi-channel AC/DC ground-fault monitor

Multi-channel AC/DC ground-fault monitor with individual relay outputs

![[Translate to North American English:] NGRM700](jpg/csm_ngrm700_01_web_list_97278228d7.jpg)

Monitor for use in high-resistance grounded systems